The "Smart Truss series" introduces a revolutionary upgrade with its newly developed "adjustable base plate system", designed to meet the demanding requirements of modern event structures, stage roofs, and temporary installations. This upgrade represents a significant leap forward in structural optimization, user convenience, and cost efficiency, offering both engineers and event organizers a reliable solution that combines precision engineering with practical functionality.

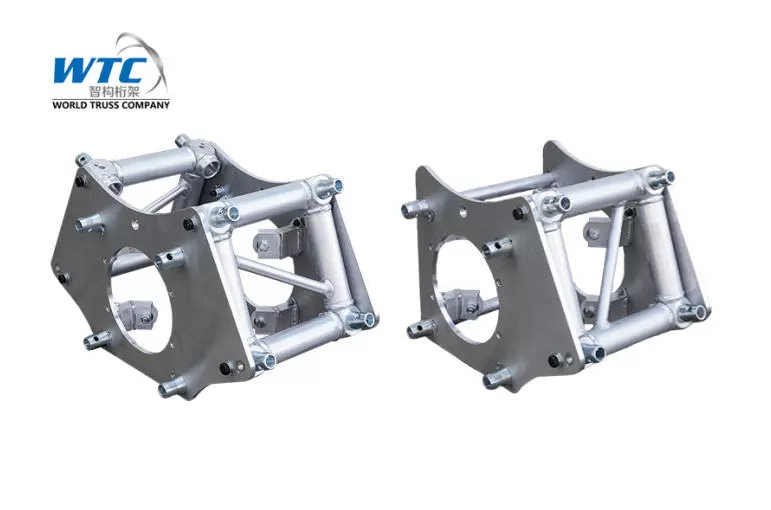

The six-way connection box has been optimized into a dual-bar direct connection structure. Reduces unnecessary weight and cost in this design, while could better cater to the user practical installation habits.

One of the most notable improvements in this upgrade is the "transformation of the traditional six-way connection head" into a simplified "dual-bar direct connection structure". By analyzing the stress distribution within the truss China system, our engineering team was able to reduce redundant material usage while maintaining the same safety margin required for load-bearing performance.

Weight Reduction:The direct connection design removes unnecessary joint housings and reinforcement parts, resulting in a lighter overall structure. This is particularly advantageous for large-scale setups where weight savings directly impact transportation costs and installation time.

Cost Efficiency: Fewer parts mean reduced production and maintenance costs. This allows event organizers and rental companies to benefit from a more cost-effective solution without compromising reliability.

User-Centric Design: The simplified connection system is more intuitive to assemble. It reduces the number of tools required and minimizes the chance of assembly errors, making it highly suitable for teams operating under tight schedules.

From a technical perspective, this direct connection approach enhances"load path efficiency", ensuring that axial forces are transferred more uniformly through the truss chords. The result is improved"torsional stability" and a longer overall service life for the structure.

The base plate is equipped with an integrated pulley system. Simply and smoothly attach the pulley to the vertical column, easily and smooth to lift up, making roof system set up easier and more efficient.

The second major improvement is the addition of a "built-in pulley system within the base plate", a feature that dramatically simplifies the process of raising and lowering the vertical columns.

Effortless Operation:The pulley assembly can be quickly attached to the upright column, allowing smooth and controlled vertical movement. This eliminates the need for heavy manual lifting, reducing physical strain on crew members and improving workplace safety.

Time-Saving Design: With its plug-and-play functionality, setup times are significantly shortened. The system is particularly beneficial for high-frequency installations where speed and efficiency are critical.

Enhanced Safety: The controlled lifting action minimizes the risk of sudden drops or uncontrolled movement, protecting both the equipment and the operators.

The pulley lifting mechanism is built using "industrial-grade bearings" and "high-tensile cables", ensuring consistent performance under repeated use. The system has been rigorously tested under load conditions exceeding industry standards, guaranteeing its reliability for long-term applications.

This base plate allows flexible horizontal and vertical expansion, so that help to decrease side crossbeams compared to traditional roof trusses. In that not only could reduces overall costs but also improves space utilization. Its feature of multi-angle adjustment could adapt to various spans, allowing quick and precise for perfect slope adjustment—solving the issue of matching multiple sizes and angles effectively, compares with conventional corner structures.

Cylindrical Lifting System – Modular and Expandable

Another defining feature of the new system is the"cylindrical lifting system", which allows "horizontal and vertical modular expansion". Unlike conventional roof truss systems that require additional side crossbeams, this design of aluminium roof truss eliminates the need for such components, resulting in:

Optimized Space Utilization: By removing unnecessary lateral members, the internal area beneath the roof is maximized. This creates more usable space for lighting, audio equipment, LED screens, and stage effects.

Cost Reduction: Fewer components mean lower material and transport costs, as well as faster assembly and dismantling times.

Structural Flexibility: The system can be easily adapted to different venue sizes and configurations without requiring custom fabrication.

From a structural engineering perspective, the cylindrical lifting mechanism allows "uniform distribution of vertical loads" across multiple support points. This reduces localized stress concentrations and enhances the"overall rigidity of the truss grid".

Multi-Angle Adjustment – Precision for Every Span

A key innovation of this upgrade is the "multi-angle adjustment capability" of the base plate system. This allows users to fine-tune the "roof slope"to match various span requirements and weather conditions.

Adaptability: Whether the installation requires a shallow slope for indoor events or a steeper pitch for outdoor setups (to facilitate water drainage), adjustments can be made on-site with minimal effort.

Precision Alignment: The adjustment mechanism provides millimeter-level accuracy, ensuring that the entire roof structure remains perfectly level and evenly loaded.

Versatility Across Projects: This feature effectively addresses one of the most common challenges in temporary structures – aligning roof geometry with multiple stage sizes and ground conditions.

This function is particularly valuable for large-scale outdoor events where"wind loading and rainwater runoff"must be considered. By achieving the optimal roof pitch, event organizers can significantly reduce the risk of water accumulation and structural instability.

Engineered for Reliability and Safety

All upgrades have been developed following"international truss and staging standards", including "EN 1090" for structural steel and aluminum components and "TÜV-certified testing procedures". Every unit undergoes load testing, dimensional inspection, and surface treatment verification to ensure compliance with global safety requirements.

Material Quality: High-strength aluminum alloy (typically EN-AW 6082-T6) is used for all primary chords and diagonals, offering an excellent balance of strength, corrosion resistance, and weight efficiency.

Durability: Precision TIG welding and reinforced node design enhance fatigue resistance, extending service life even under demanding conditions.

5Anodized or powder-coated finishes are available to improve resistance to wear, scratches, and harsh weather exposure.

The Complete Solution for Modern Event Structures

The upgraded adjustable base plate system is not just a hardware improvement—it is a "comprehensive solution" that addresses key concerns of event professionals: speed of installation, safety, structural flexibility, and cost efficiency. Whether used for concert stages, exhibition halls, outdoor festivals, or corporate events, this system provides:

* Faster assembly with fewer components

* Lighter transport loads, reducing logistics costs

* Improved safety and ergonomics for installation teams

* Greater adaptability for diverse stage designs and venues

* Long-term durability with low maintenance requirements

With this upgrade, the Smart aluminium truss for sale continues to set new benchmarks for "innovation in truss engineering", offering peace of mind for production companies, rental houses, and event organizers worldwide.