In the world of professional stage design and event construction, the aluminum truss system has become an irreplaceable structure that supports creativity and stability. With the growing demand for high-performance and versatile stage solutions, WTC aluminum truss stands out for its remarkable combination of durability, flexibility, and aesthetics. Designed under strict production standards and inspired by advanced craftsmanship, WTC trusses provide reliable frameworks for concerts, exhibitions, and architectural displays. Each aluminum truss system produced by WTC reflects precision engineering, ensuring both strength and ease of assembly while maintaining a sleek, modern look suitable for any professional setup.

At the heart of every WTC aluminum truss lies advanced engineering that merges artistry with industrial expertise. Through years of dedicated research and technical refinement, WTC has developed a production process that integrates high-grade materials and strict quality control from start to finish. Every aluminum truss system is designed with multi-dimensional precision—from structure design and welding to load-bearing analysis and surface finishing. The result is a truss that not only meets global standards but also excels in reliability and aesthetic value. This commitment to quality enables WTC to serve diverse industries across Europe, Asia, and Oceania, offering structures that adapt to the demanding needs of international clients.

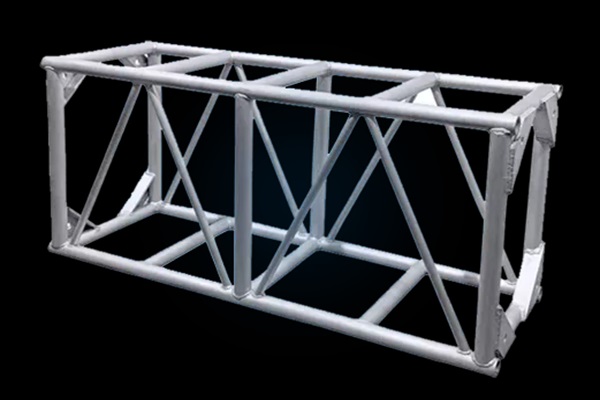

Professionals across entertainment, exhibitions, and construction sectors consistently choose WTC aluminum truss systems for their lightweight yet exceptionally strong design. The high-grade aluminum used in WTC products ensures corrosion resistance and long-term performance, even in challenging environments. In addition, the modular design of each aluminum truss system allows for quick installation and flexible configuration. Whether used for lighting setups, stage roofs, or large-scale exhibition frameworks, WTC trusses maintain stability while simplifying logistics. Their compatibility with various accessories and connection systems also makes them an efficient solution for professionals seeking both form and function. WTC's emphasis on craftsmanship ensures that every aluminum truss performs flawlessly, even under the most complex setups.

Behind every WTC aluminum truss system lies a rigorous process guided by innovation and precision. From raw material inspection to welding and final load testing, each step follows international standards to guarantee safety and strength. WTC employs advanced testing technologies to ensure that every aluminum truss can withstand both static and dynamic loads, providing long-term dependability for any structure. The company's focus on precision manufacturing also enhances the uniformity of product quality, reducing installation errors and improving assembly efficiency. WTC's dedication to technological advancement and process optimization reflects its continuous pursuit of excellence in every aluminum truss system it creates.

As global stage and event design continue to evolve, the role of aluminum truss systems will become increasingly important in shaping modern event architecture. WTC is committed to pushing the boundaries of innovation by combining advanced design concepts with high-quality materials. With an unwavering spirit of craftsmanship, the company continuously refines its aluminum truss designs to meet the diverse needs of creative professionals worldwide. WTC's vision is to support artistic expression through safe, reliable, and visually appealing truss systems that redefine structural possibilities. With its strong international presence and dedication to quality, WTC aluminum truss systems will continue to lead the industry toward a more efficient and aesthetic future.