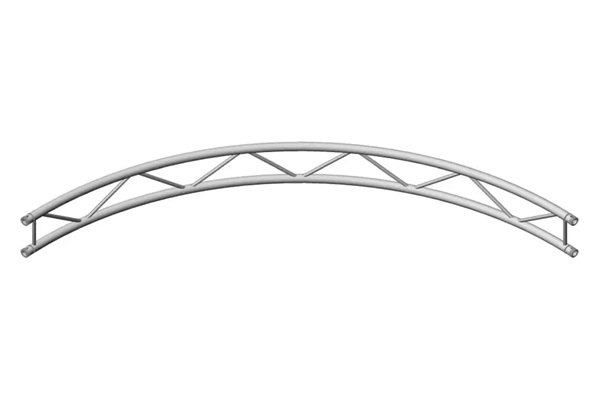

In modern stage construction and event engineering, the ladder truss plays a vital role in creating stable and flexible structures. Whether it supports lighting equipment, sound systems, or decorative elements, the safety of a ladder truss directly affects the reliability of the entire stage. A well-engineered aluminum ladder truss ensures not only structural strength but also protection for performers, technicians, and audiences. Safety begins with design precision, high-quality materials, and strict production control, and WTC aluminum ladder truss demonstrates excellence in each of these areas. Through advanced craftsmanship and consistent innovation, WTC provides truss systems that meet international standards and perform dependably in demanding conditions.

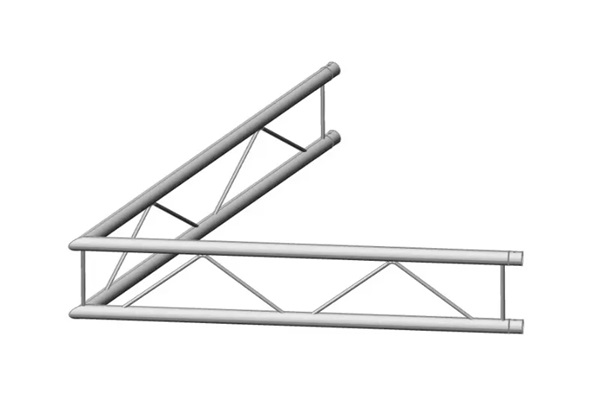

Every WTC aluminum ladder truss is designed with scientific precision to ensure stability under dynamic loads. During production, the materials are carefully selected to maintain high strength while keeping the truss lightweight. The ladder truss adopts a geometric framework that evenly distributes stress across its tubes, preventing deformation even under heavy equipment or movement. Each aluminum ladder truss undergoes a rigorous testing process that includes load-bearing analysis, weld integrity inspection, and alignment verification. These procedures ensure that the finished truss meets strict safety requirements before leaving the factory. By adhering to high production standards and detailed quality management, WTC guarantees that every ladder truss provides a safe and stable foundation for professional stage use.

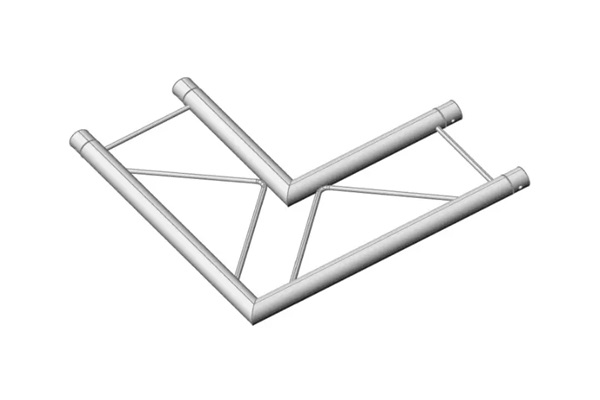

The safety of a ladder truss system depends greatly on its design. WTC engineers optimize each aluminum ladder truss to achieve maximum strength with minimal material stress. The use of precision-welded joints enhances load transfer efficiency, reducing weak points that could compromise safety. The aluminum alloy used in WTC's ladder truss provides excellent resistance to corrosion, ensuring long-term performance even in outdoor environments. Furthermore, each truss is engineered for seamless assembly and accurate connection, preventing misalignment that can affect structural balance. By focusing on both mechanical reliability and design simplicity, WTC ensures that every aluminum ladder truss remains safe and efficient in practical use.

Safe usage of aluminum ladder truss begins with proper installation and handling. WTC designs its ladder truss systems with user-friendly connection mechanisms that ensure secure fitting without excessive force or complex tools. During setup, it is essential to verify that each section of the ladder truss is correctly aligned and fastened according to manufacturer guidelines. The light weight of WTC's aluminum structure makes handling easier, minimizing the risk of improper lifting or assembly errors. Routine inspections before and after events help identify wear or damage early, maintaining the safety performance of the aluminum ladder truss over time. WTC's design philosophy emphasizes not only the structural quality of the truss itself but also the overall safety of its usage process, making it ideal for both temporary and permanent installations.

At the core of WTC's manufacturing philosophy lies an unwavering commitment to safety and reliability. Each aluminum ladder truss reflects the company's dedication to precise engineering, superior materials, and meticulous craftsmanship. By integrating scientific production methods with strict testing standards, WTC ensures that every ladder truss system can withstand professional demands in concerts, exhibitions, and architectural displays. The combination of innovative design and careful inspection provides confidence to users across Europe, Asia, and Oceania. Safety is not an afterthought but a fundamental principle guiding every stage of production. Through continuous improvement and the spirit of craftsmanship, WTC aluminum ladder truss will continue to set new benchmarks for safety and performance in the global stage industry.