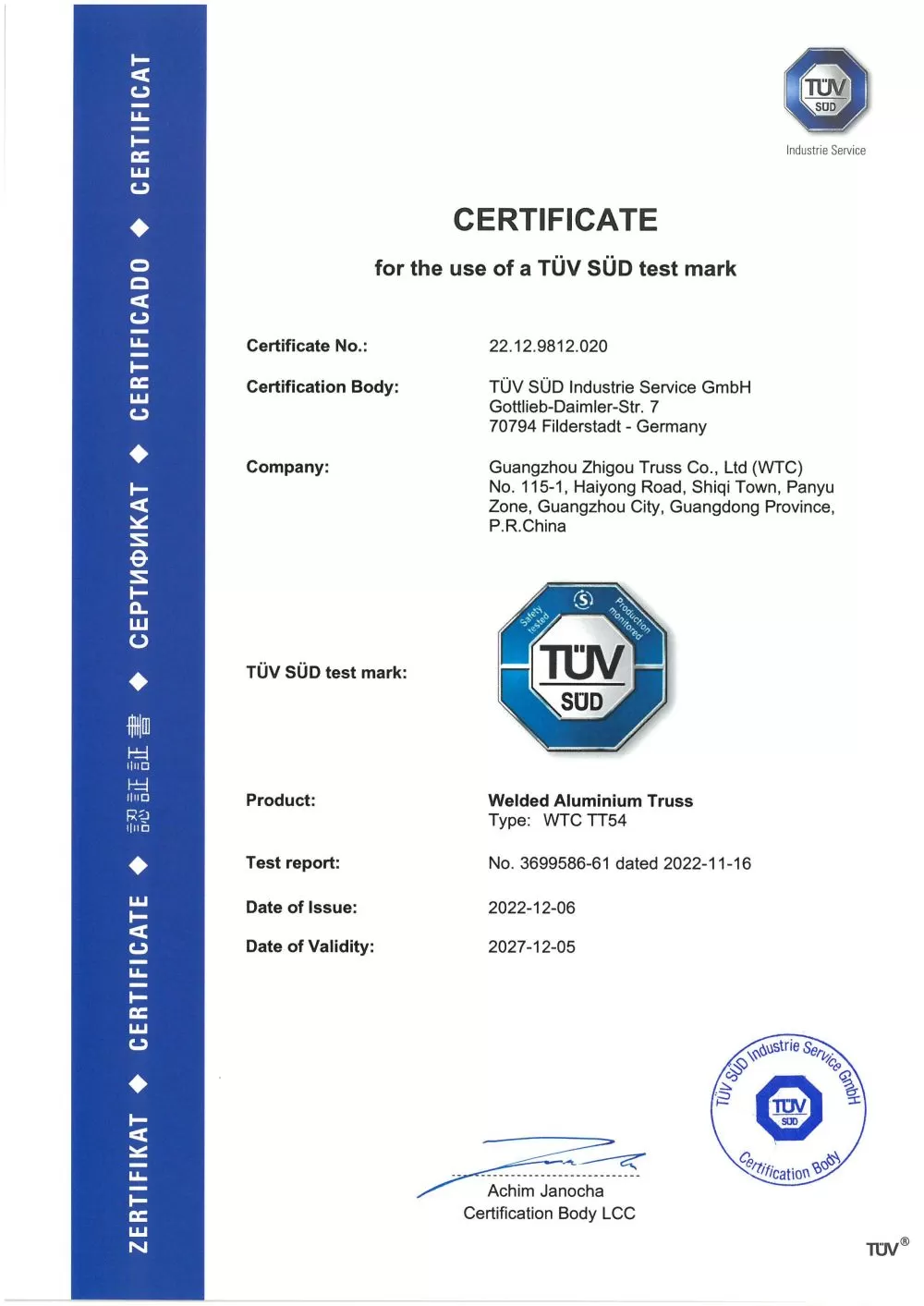

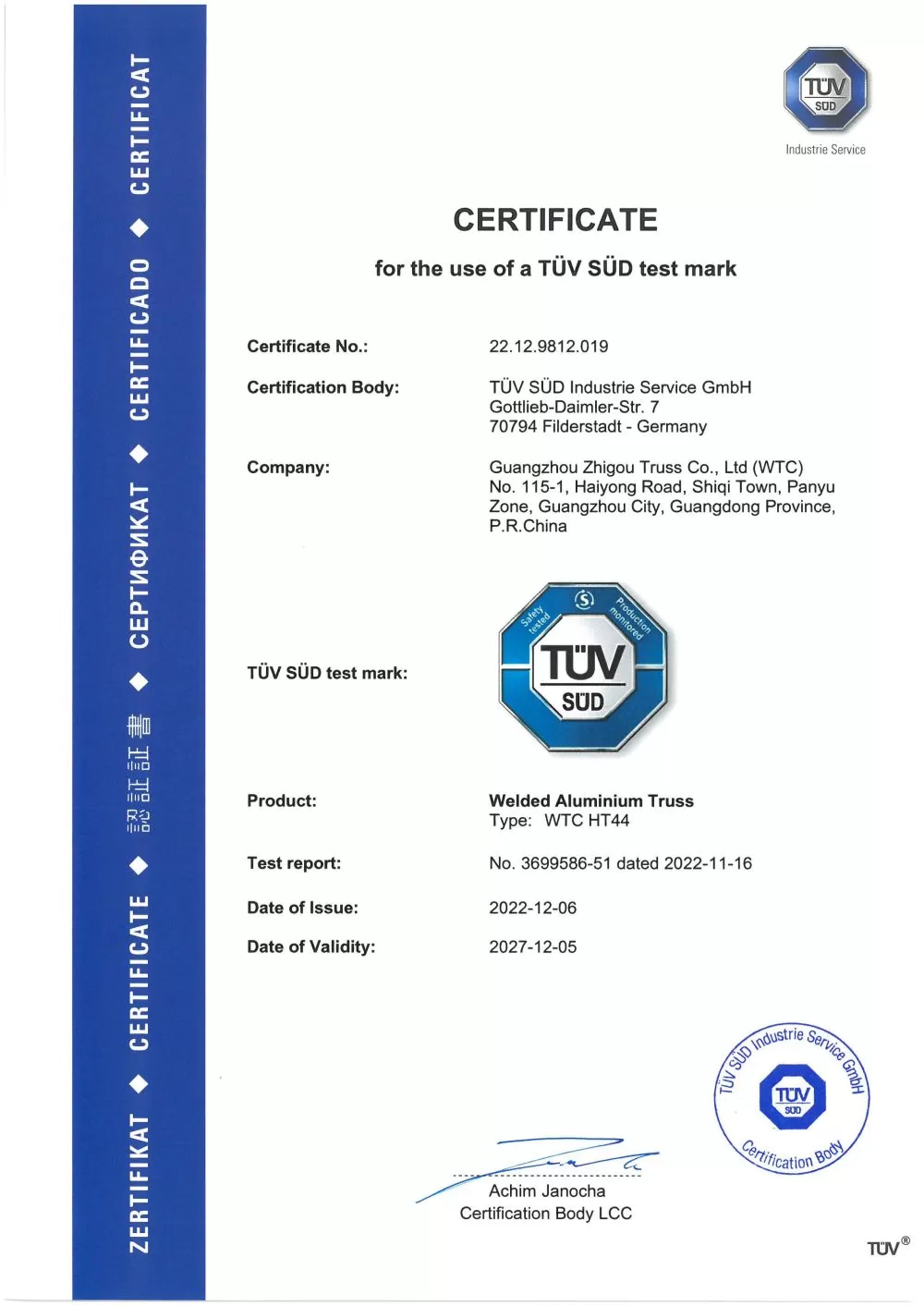

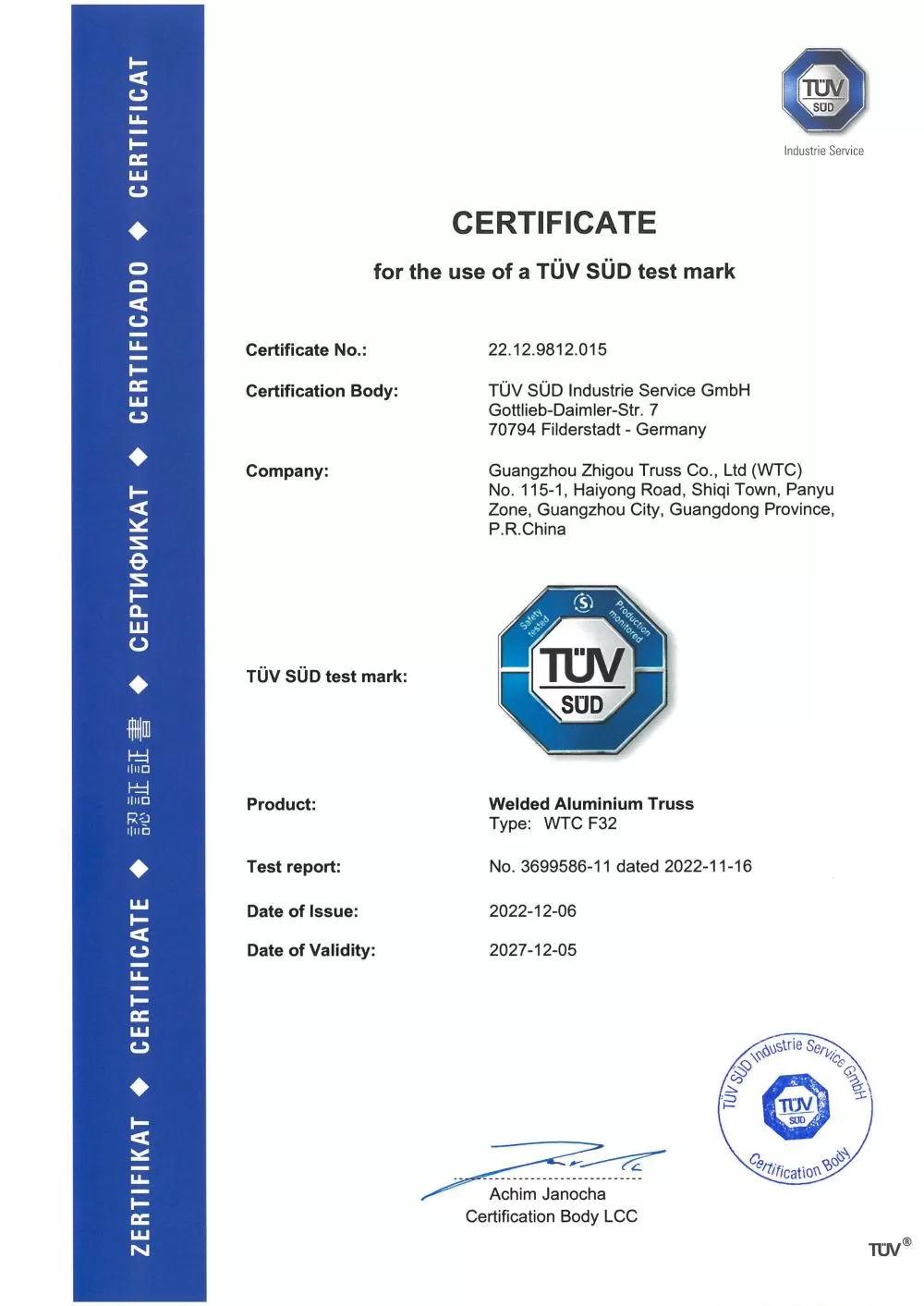

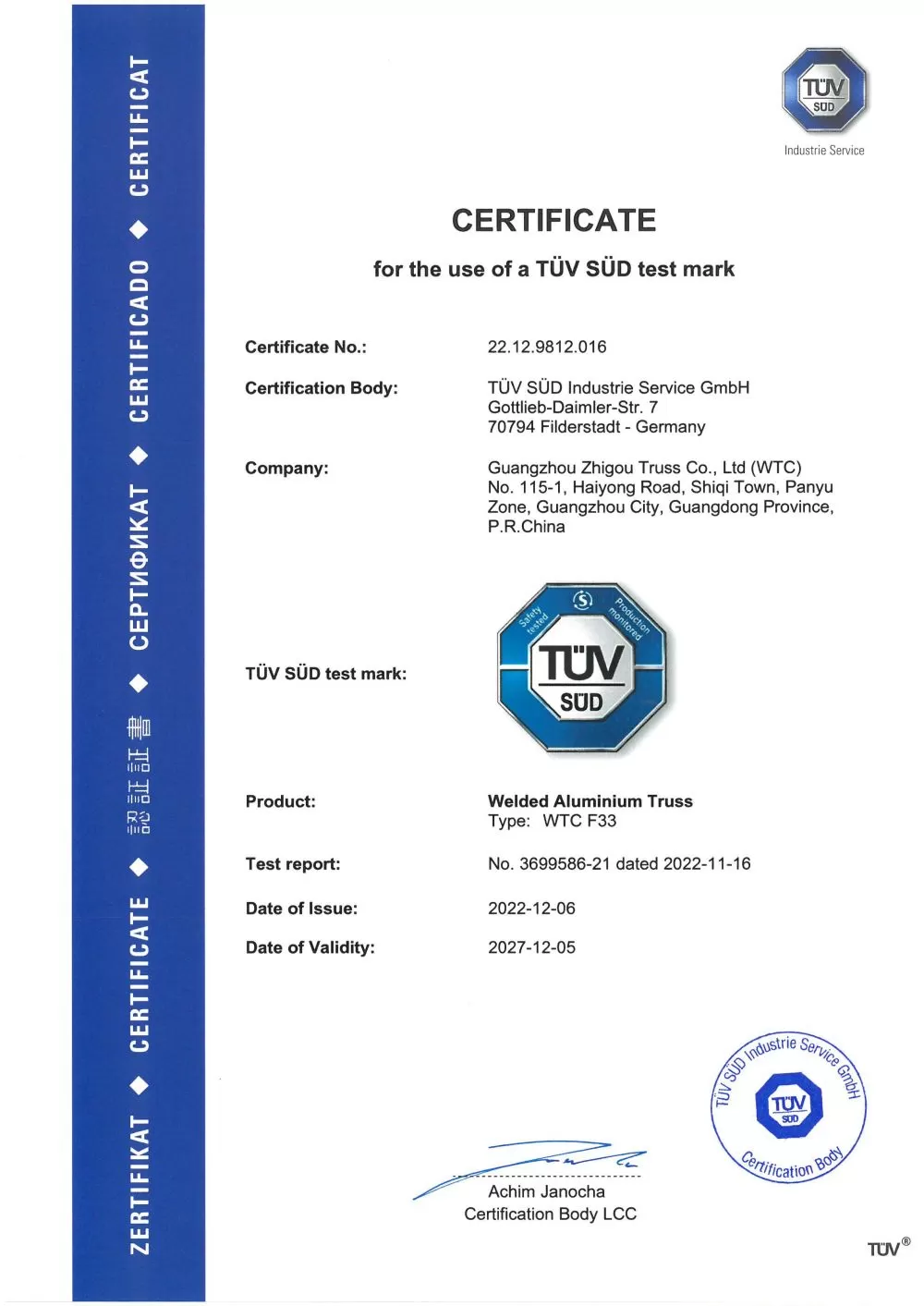

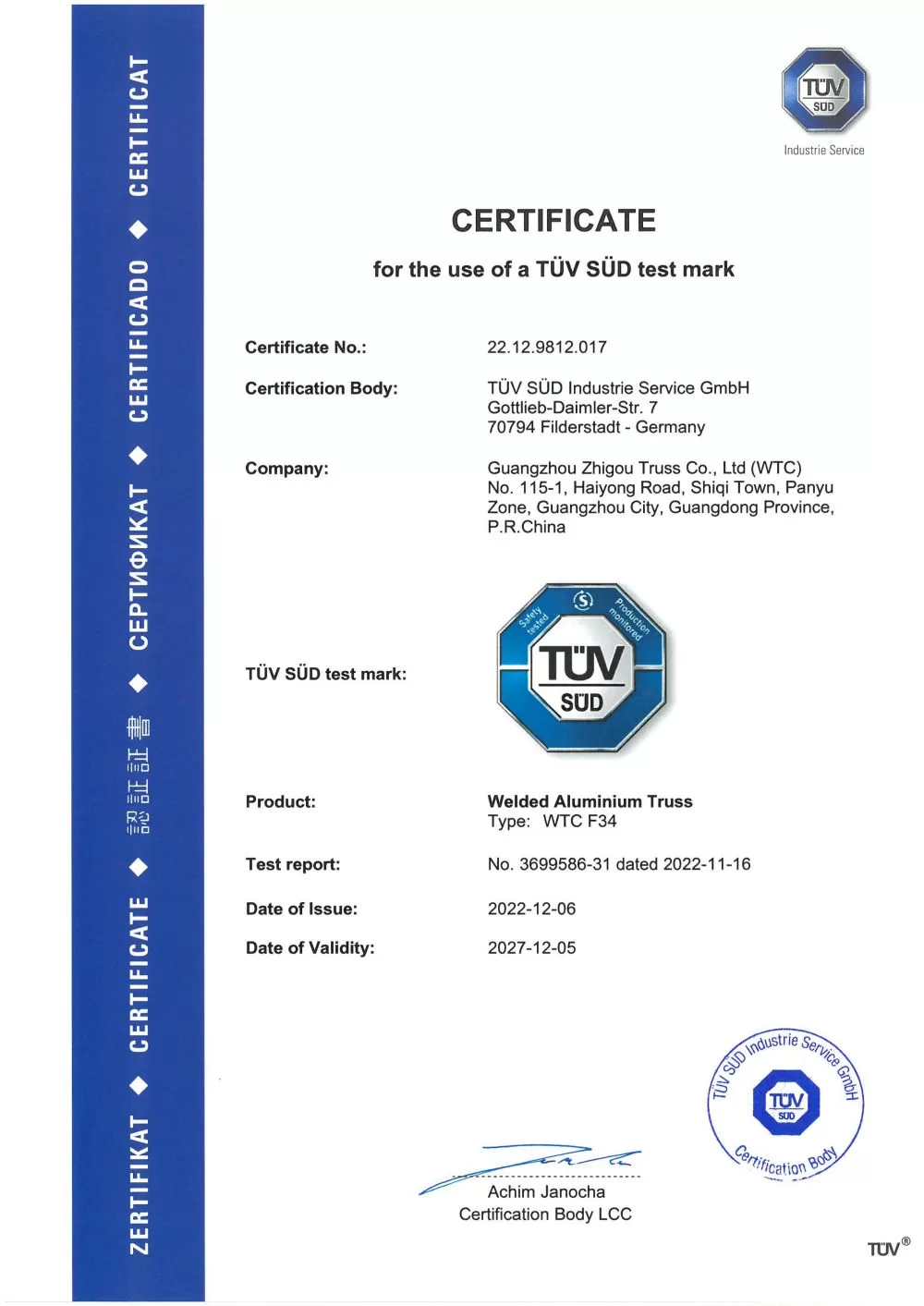

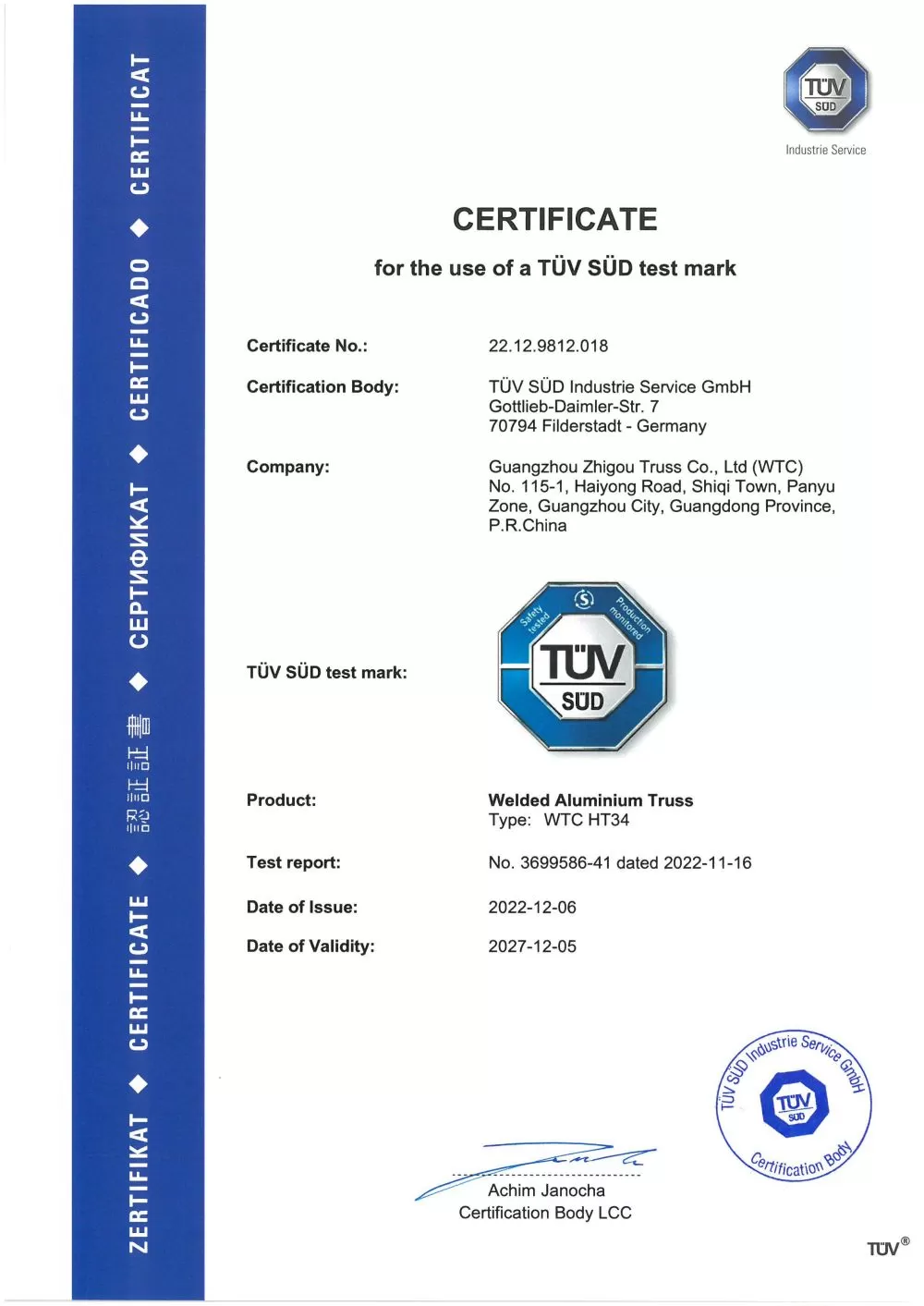

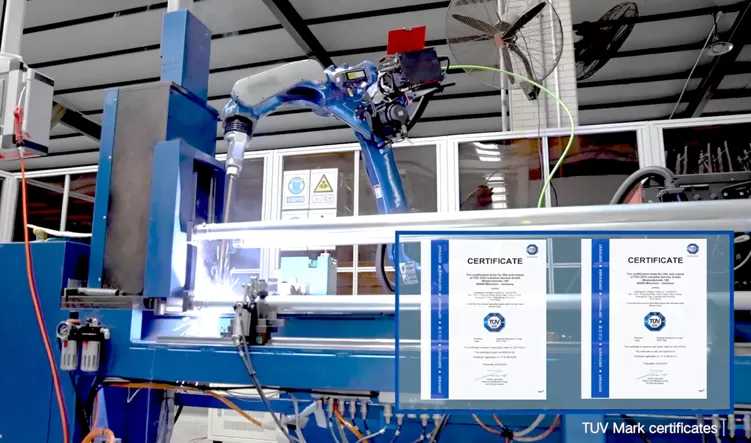

At WTC, our production standards are rooted in uncompromising attention to material quality, structural engineering, and load-bearing performance—ensuring every truss system we manufacture meets the highest levels of reliability and safety.

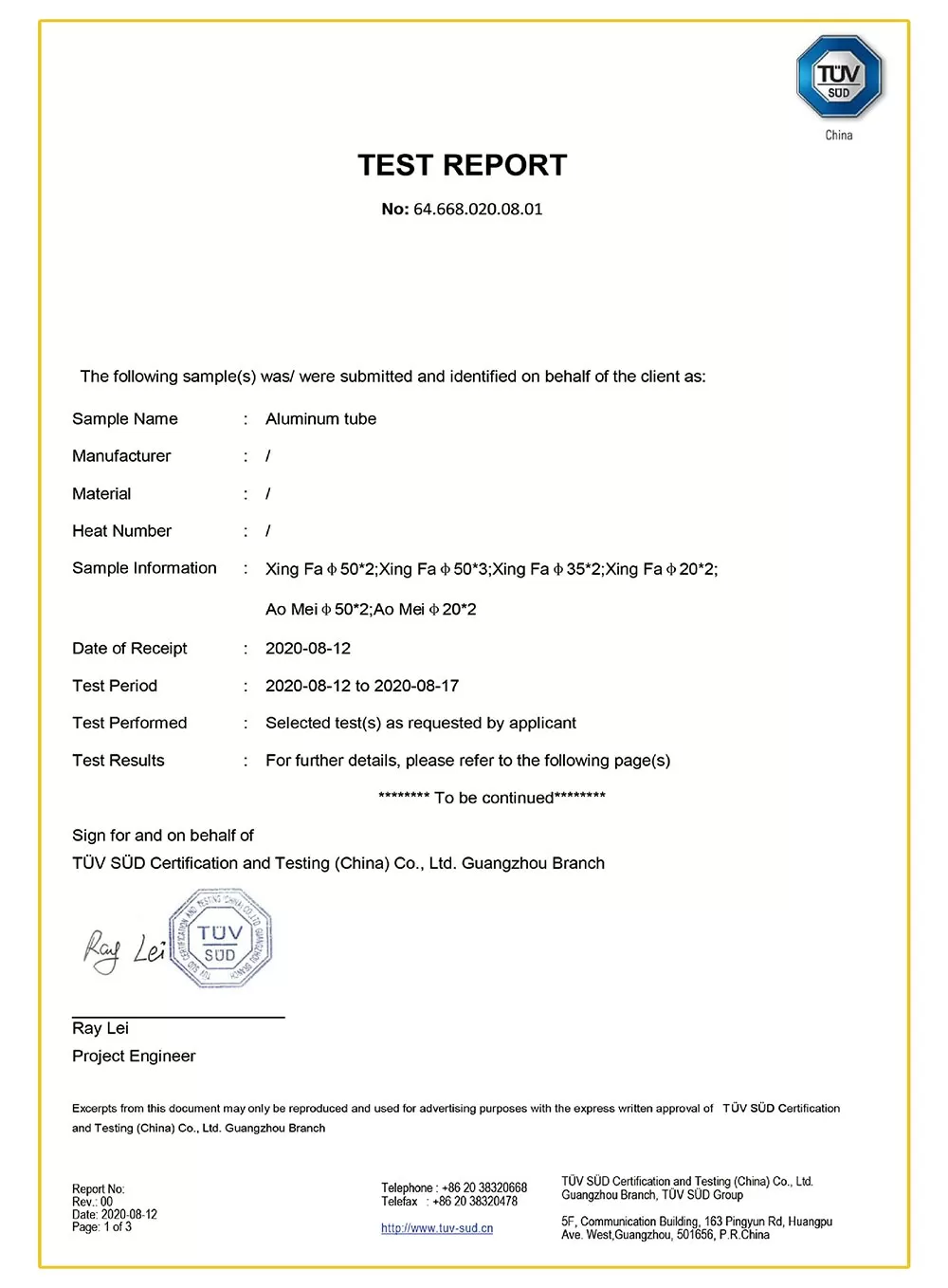

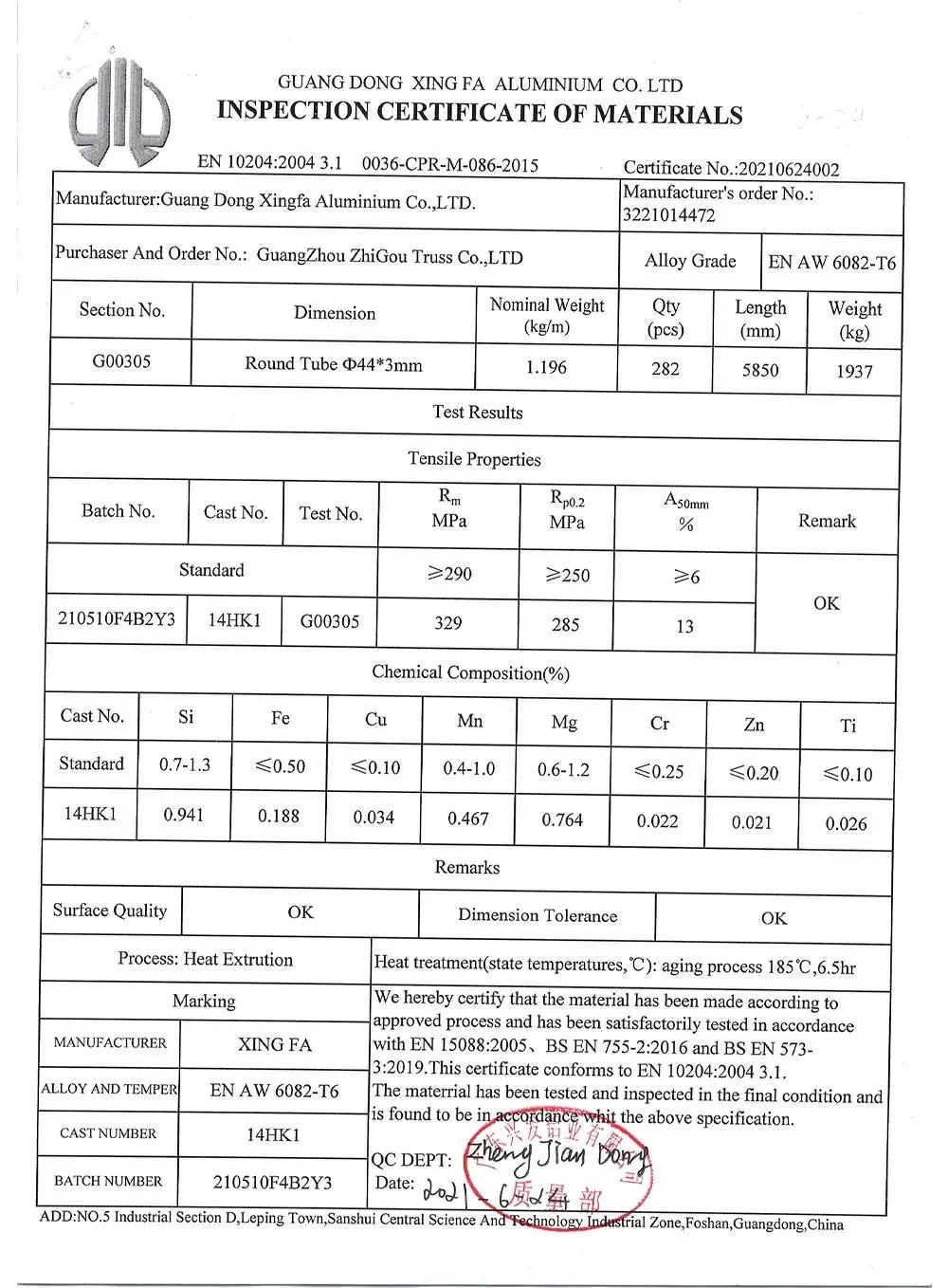

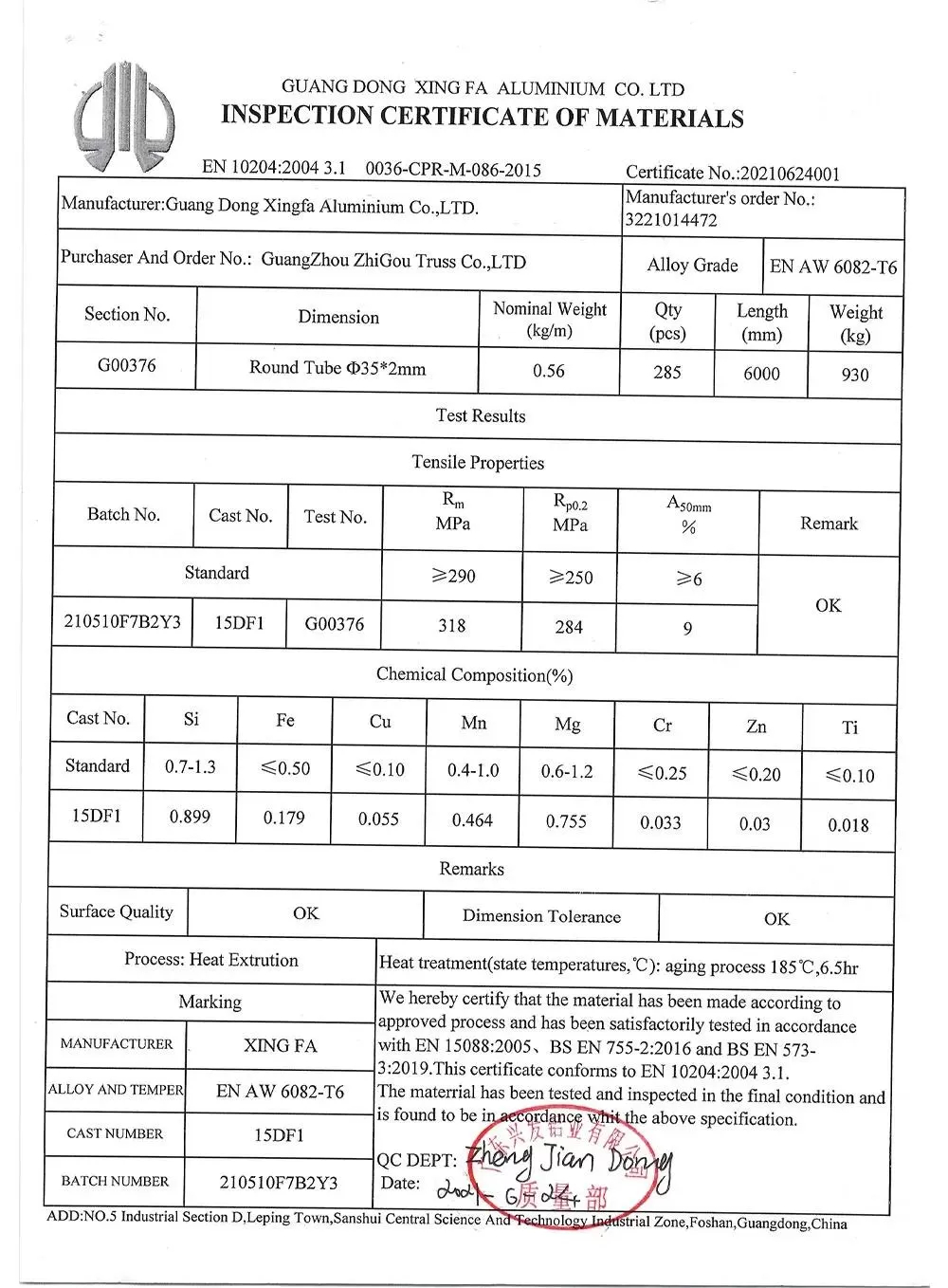

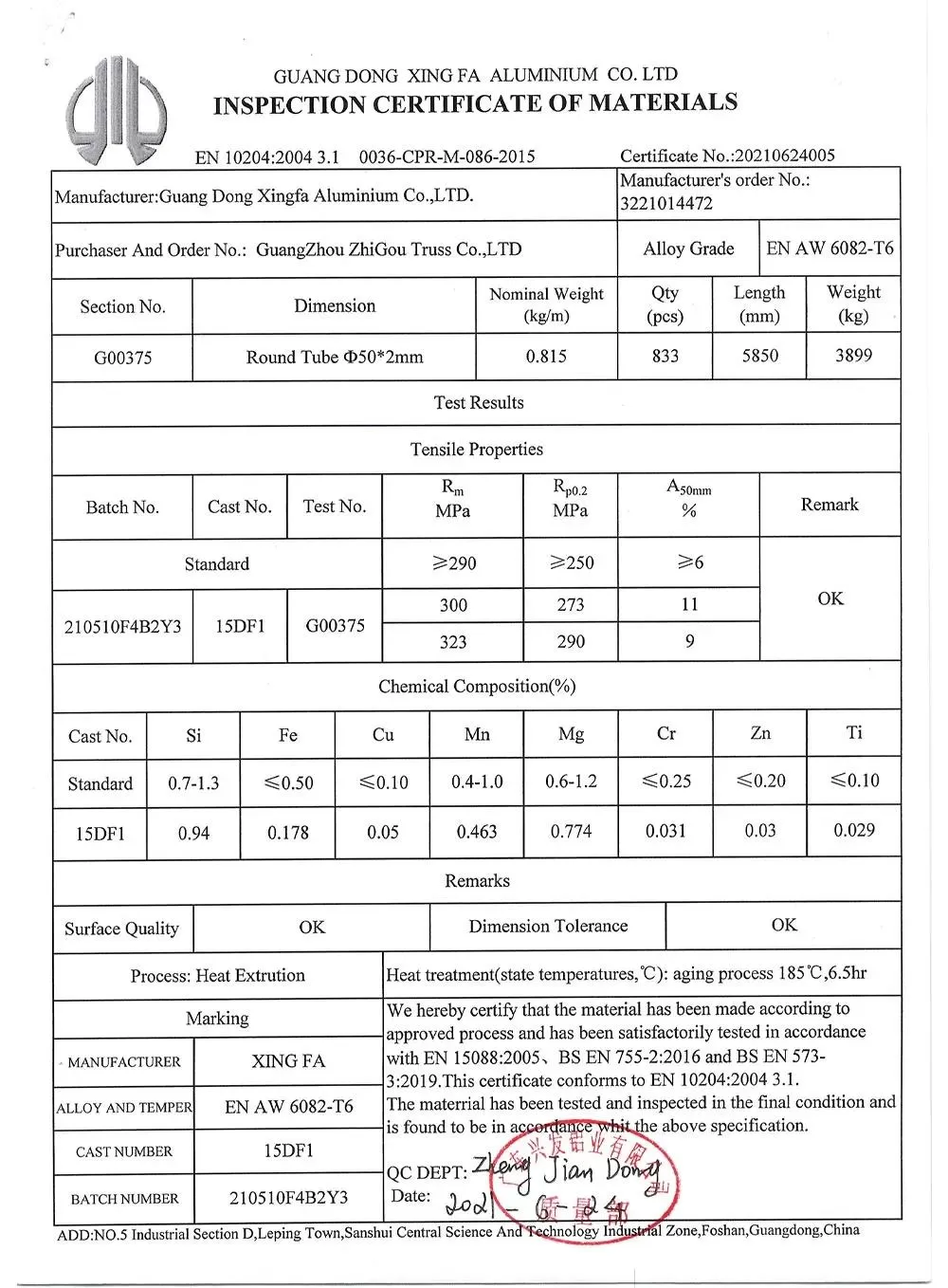

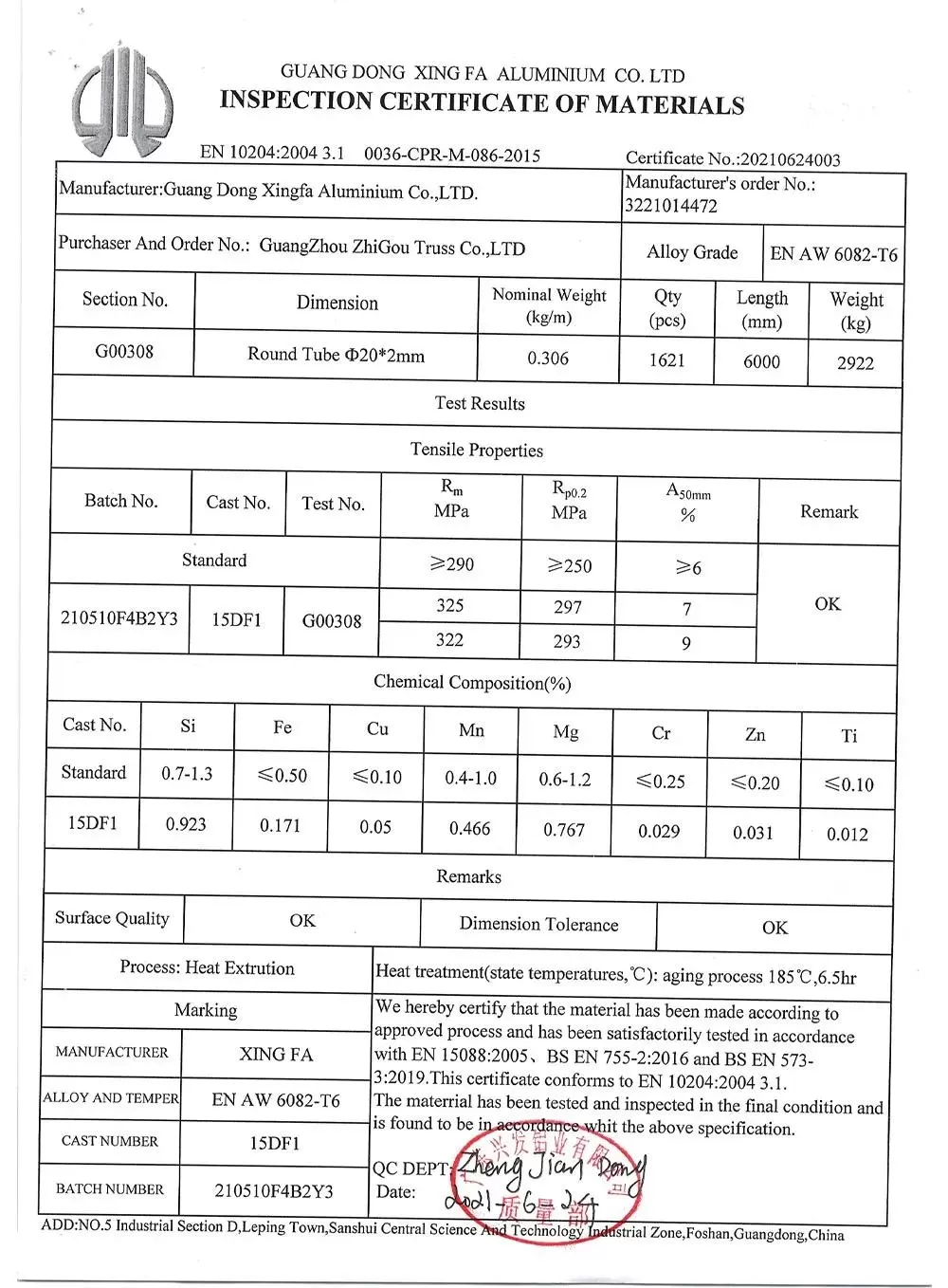

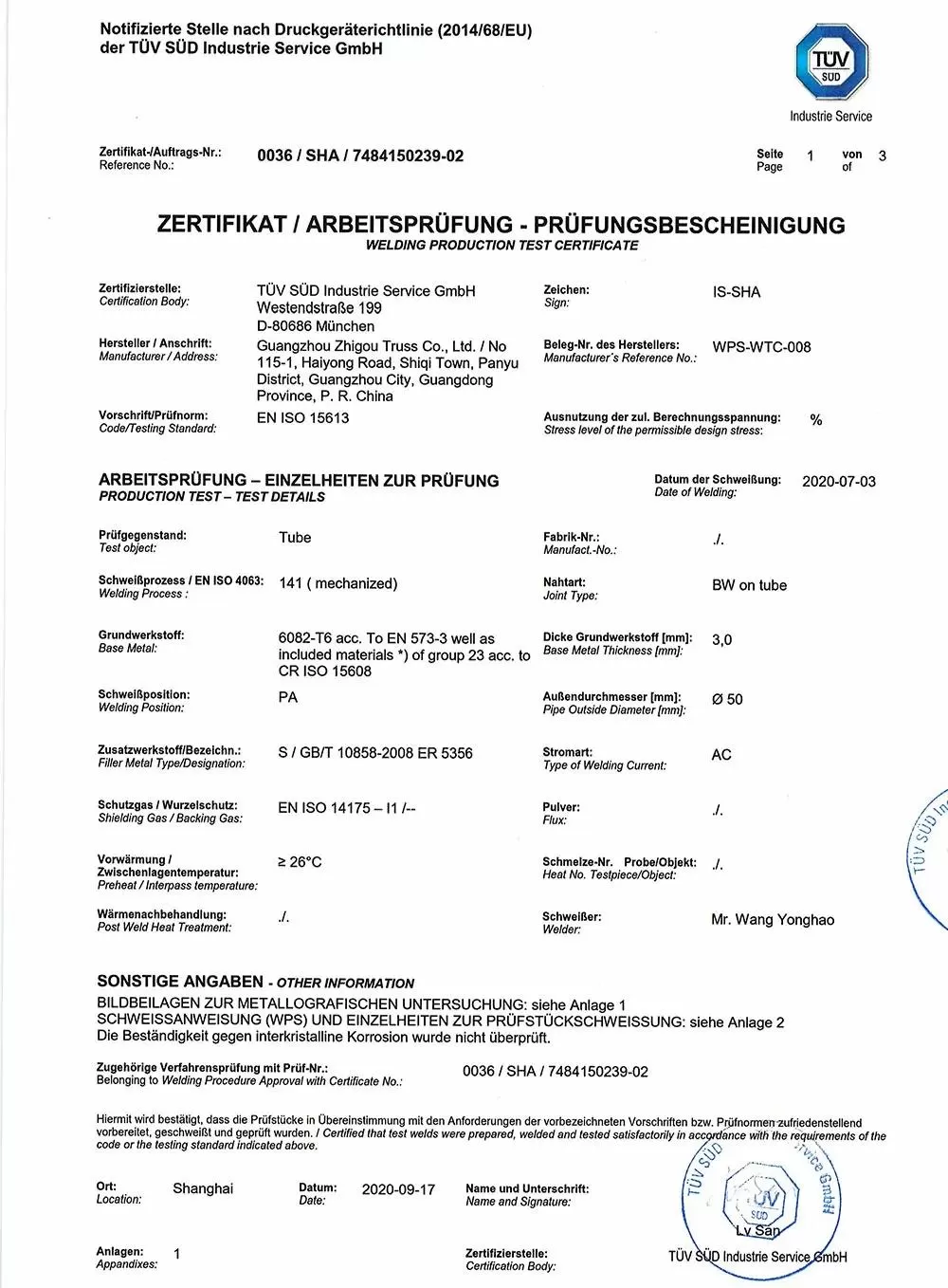

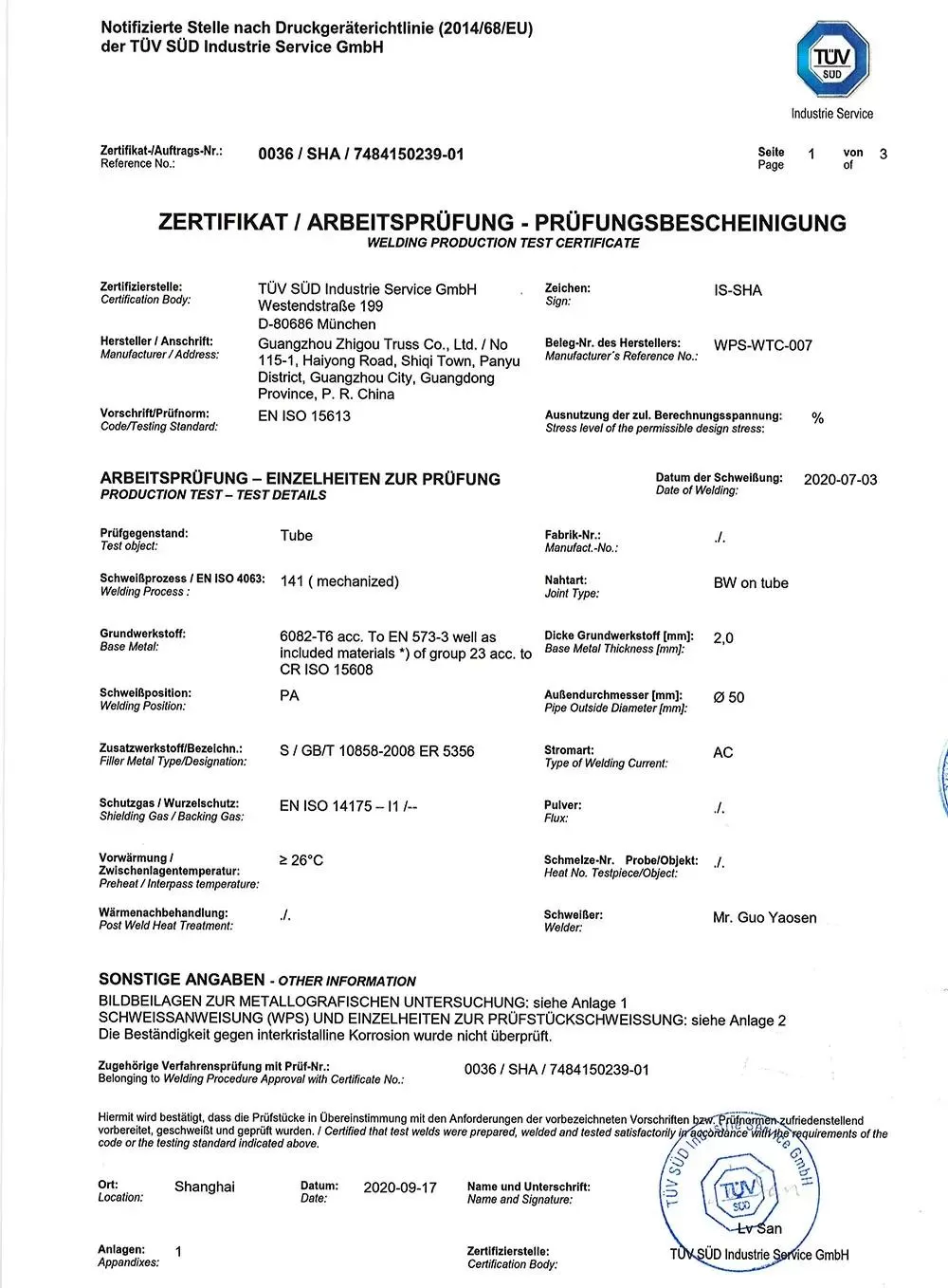

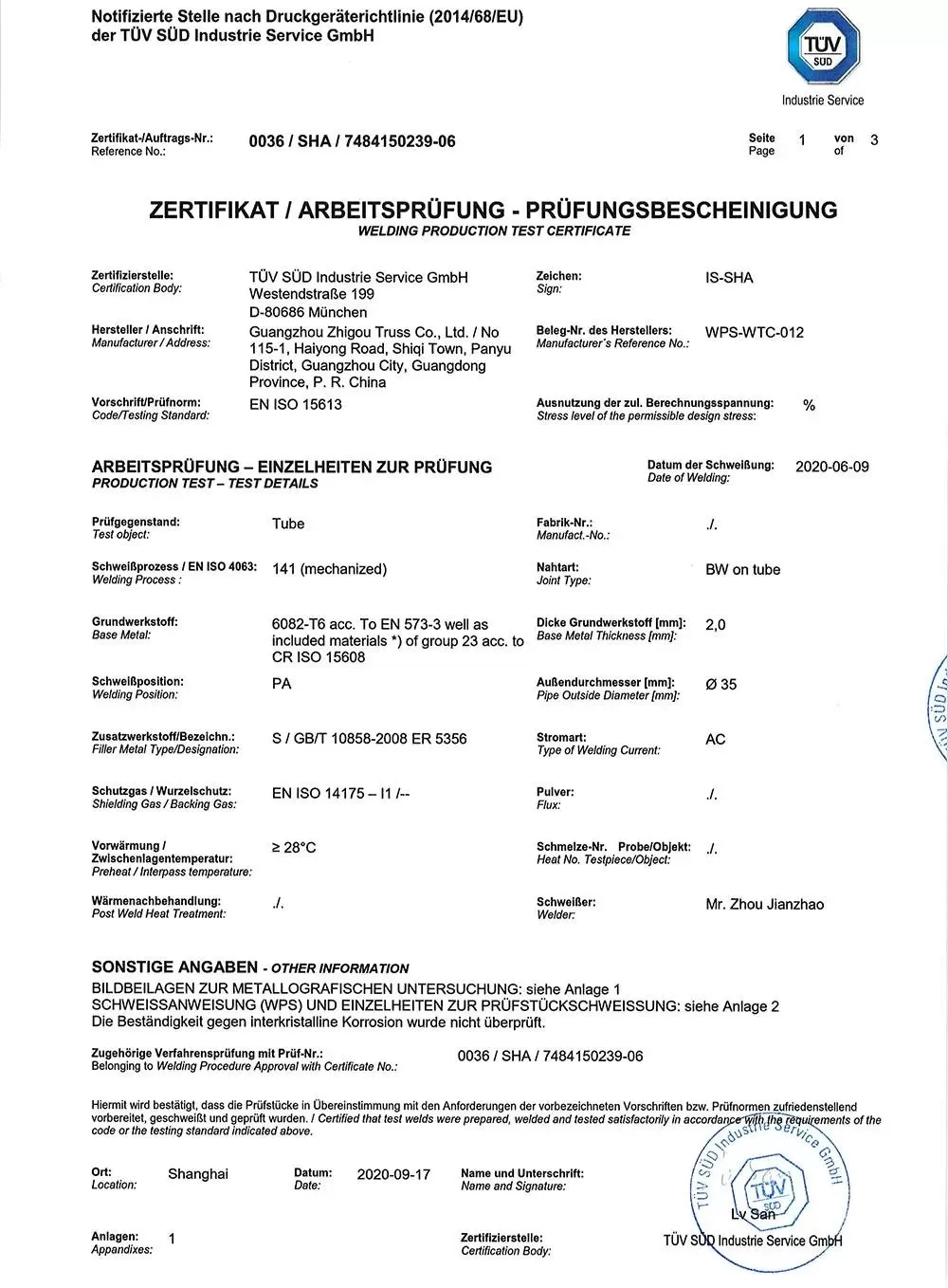

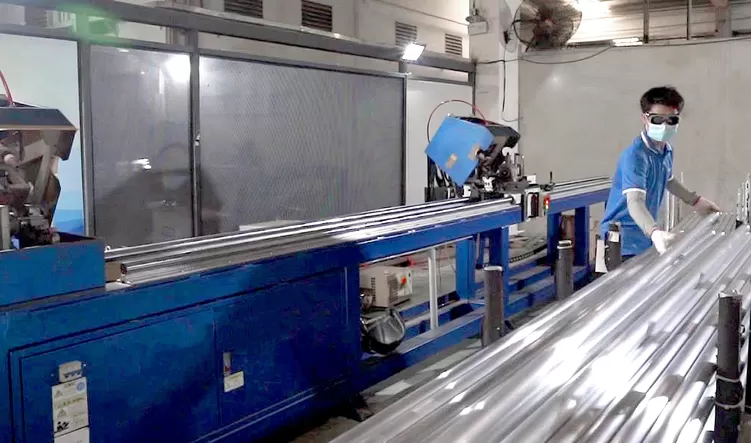

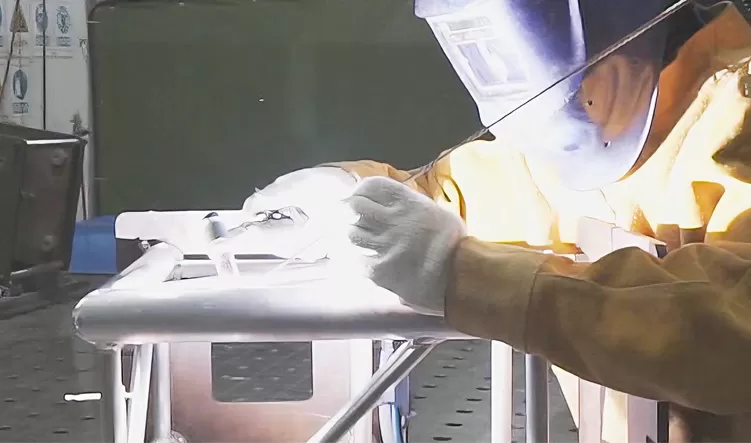

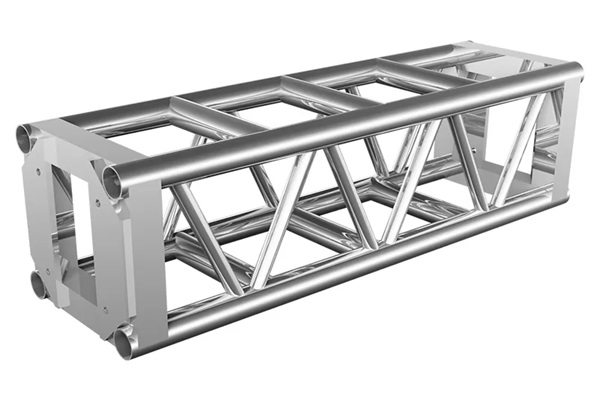

Premium Material Selection

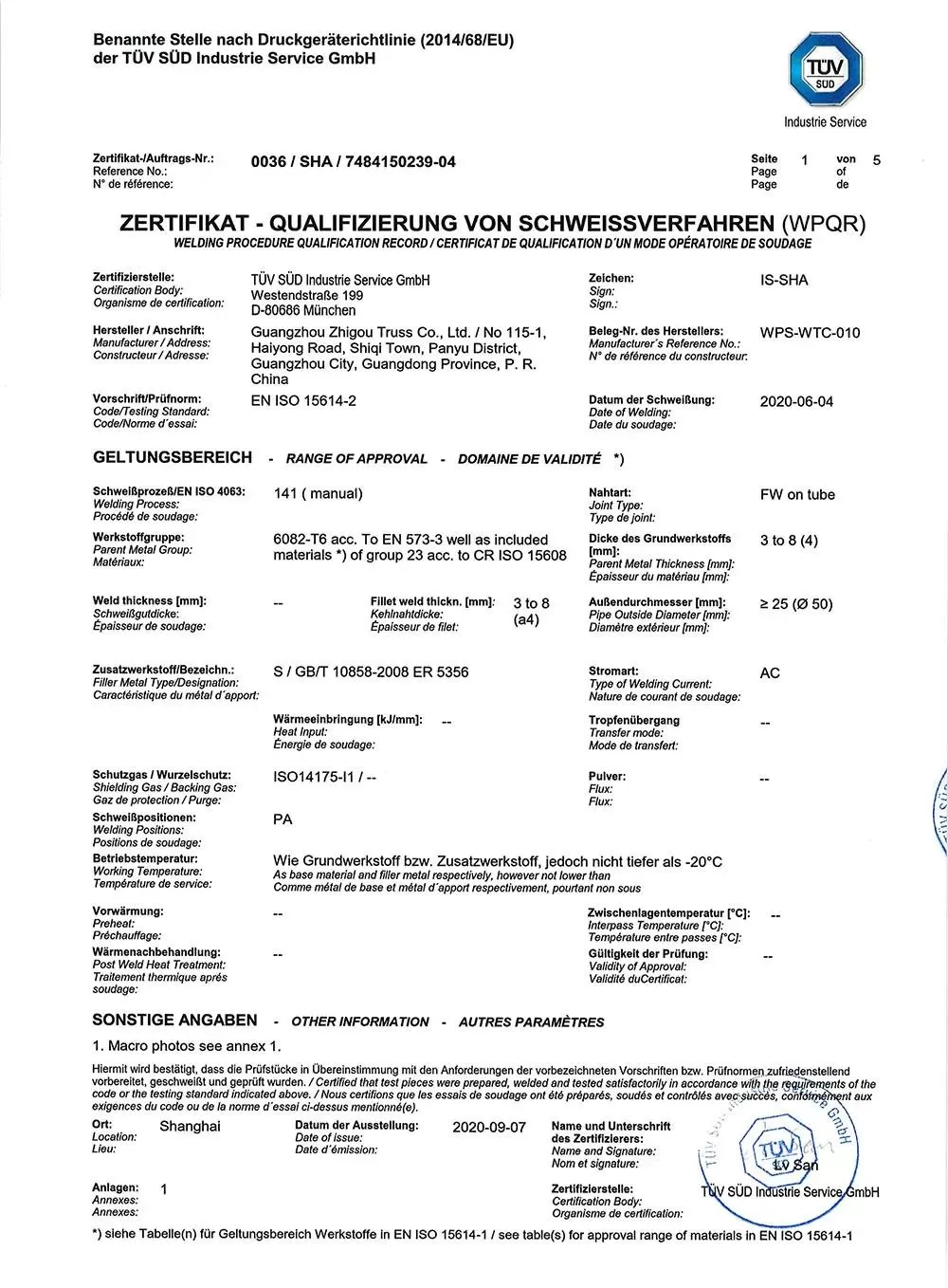

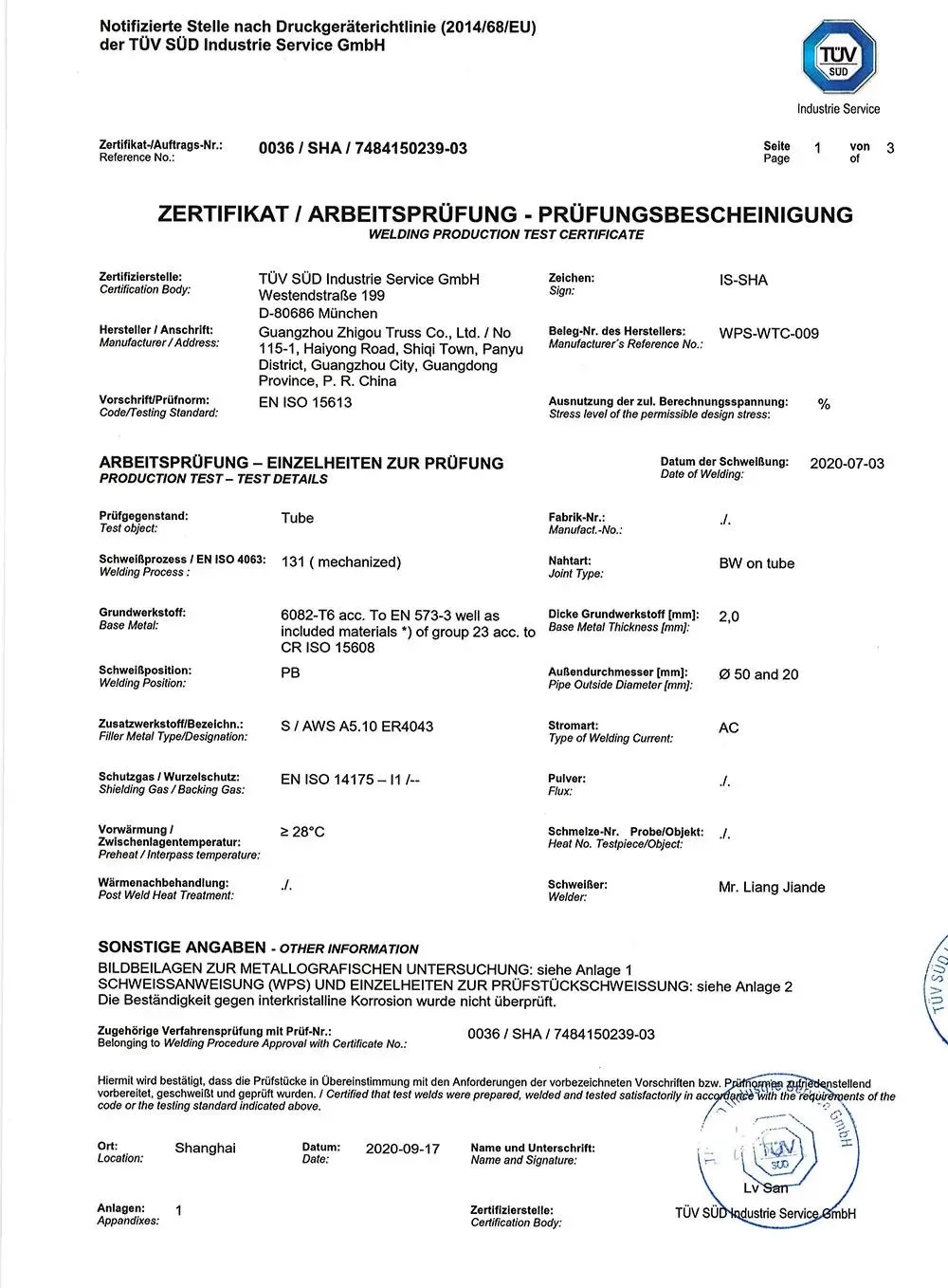

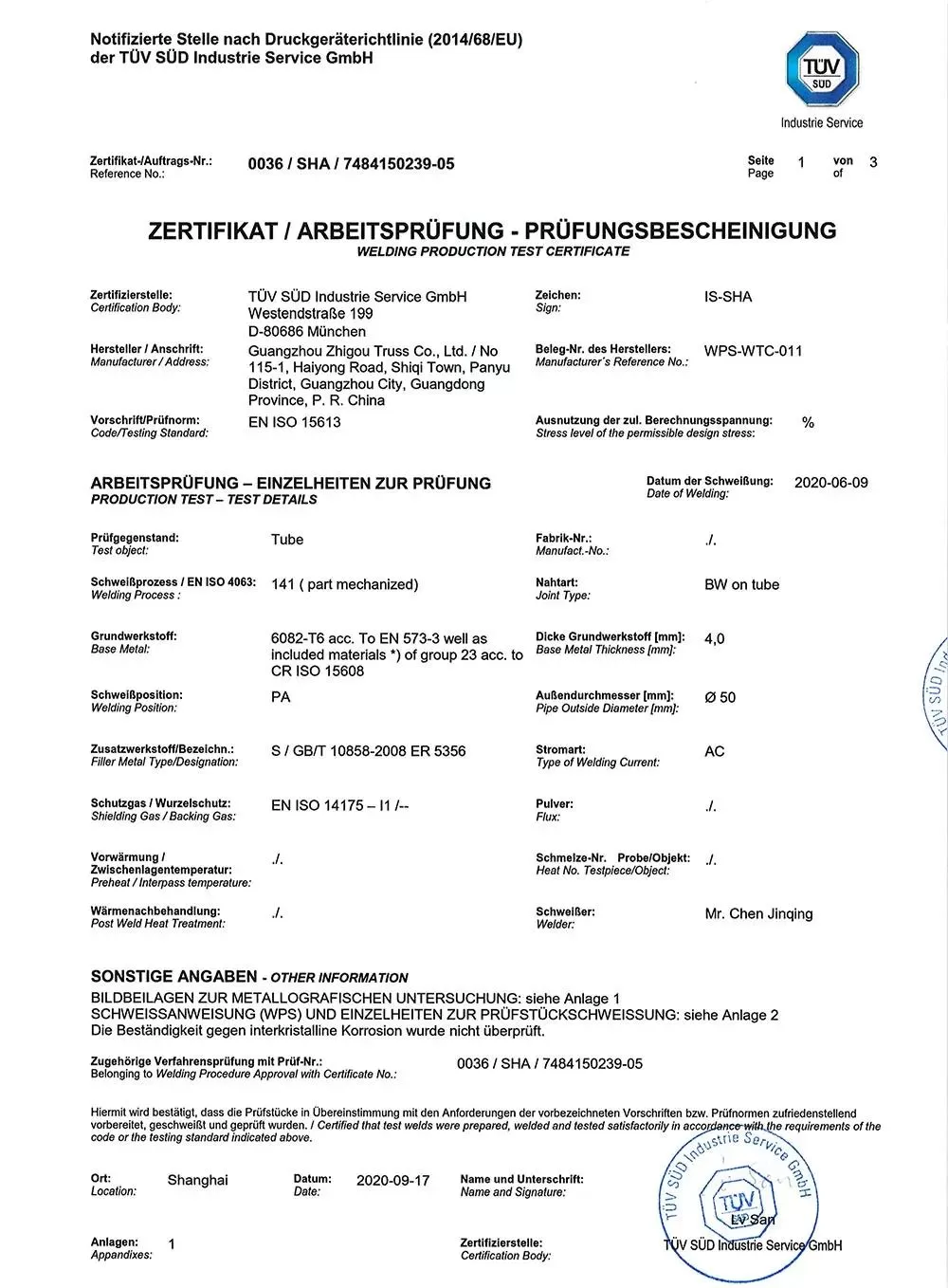

WTC uses high-grade EN AW-6082 T6 aluminum alloy across all truss products, renowned for its excellent strength-to-weight ratio and corrosion resistance. We enforce strict control on material hardness, maintaining a minimum of 16HW, which significantly enhances durability and structural stability. Additionally, we ensure uniformity in the wall thickness of both main tubes and vice tubes to prevent weak points and optimize load distribution.

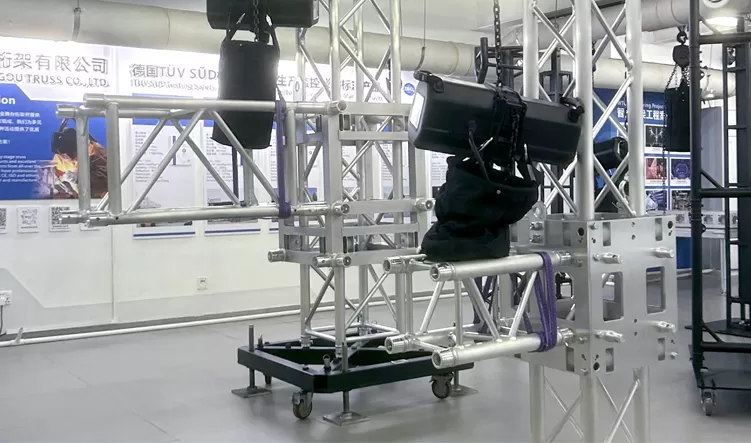

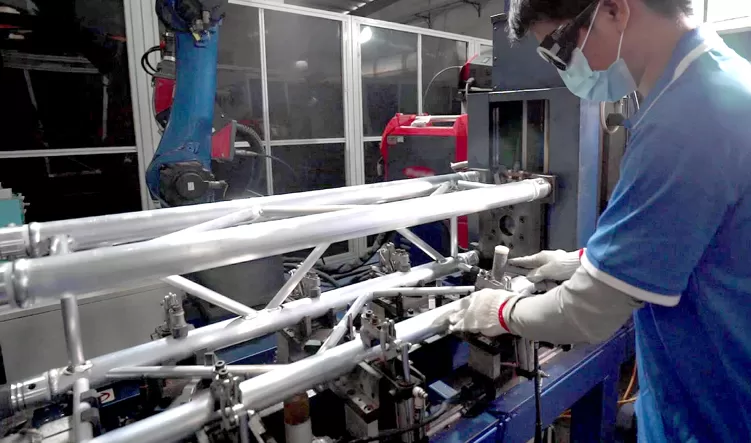

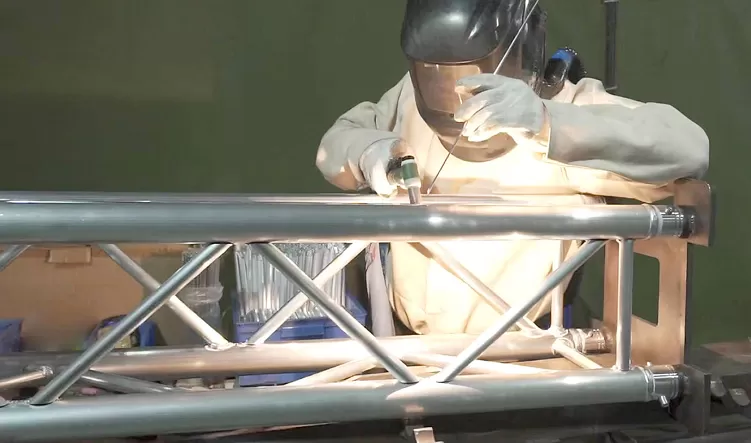

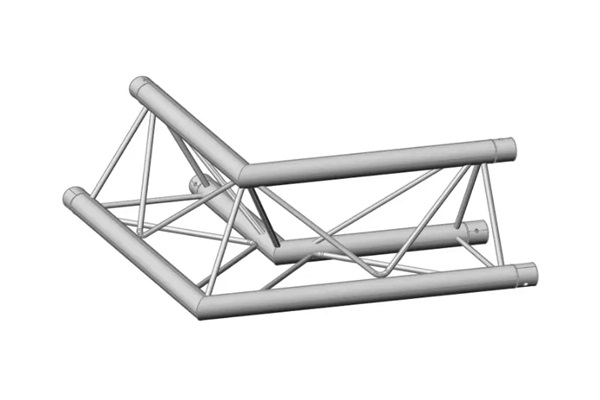

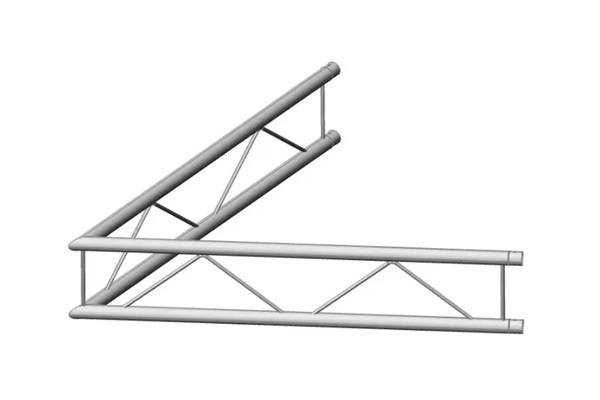

Engineering-Centric Structural Design

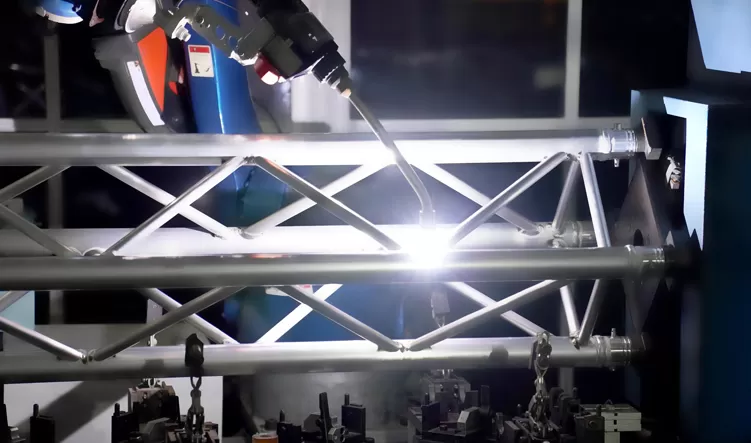

Every WTC truss structure is engineered with precision. Our design strictly follows the principles of triangular bracing, particularly focusing on the optimal angle between brace components. This geometry minimizes deformation under load and maximizes rigidity, resulting in enhanced stability and resistance to dynamic forces during use.

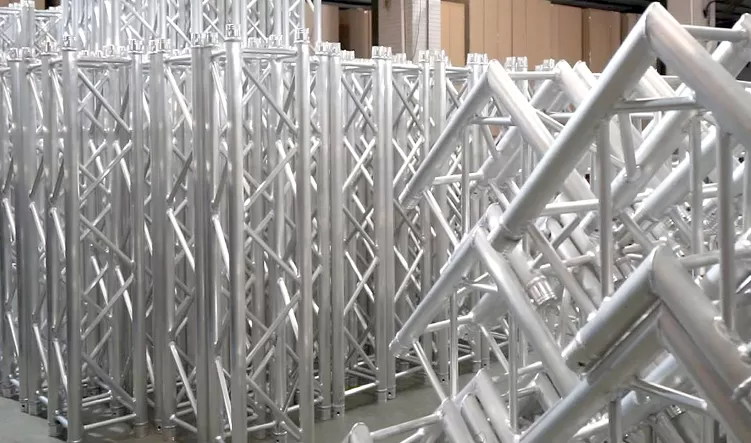

Superior Load Capacity and Long-Span Performance

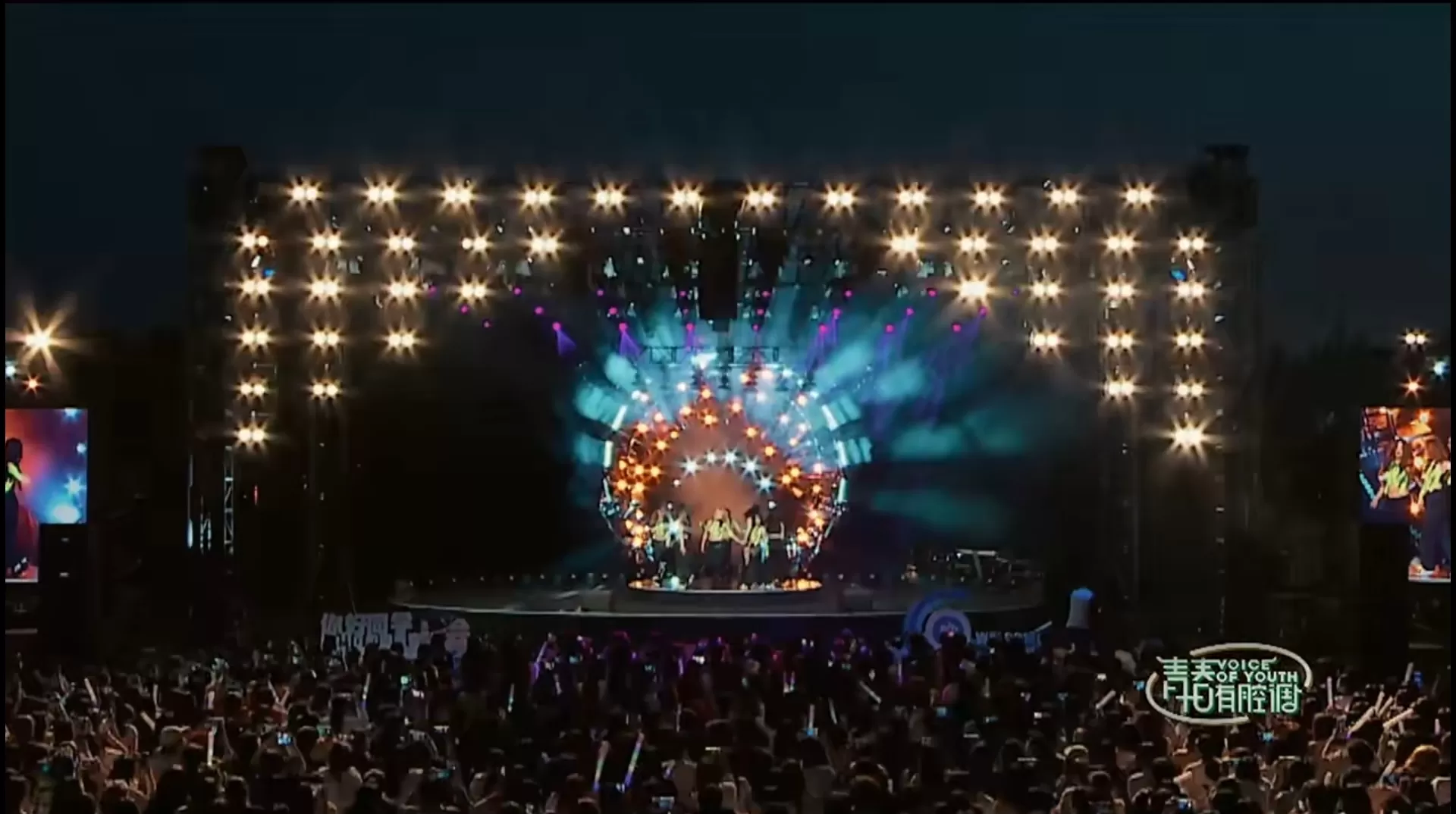

WTC trusses are known for their outstanding load-bearing capacity, even across extended spans. Thanks to both advanced structural design and high-quality material selection, our trusses maintain their form under high stress, resisting bending and deflection. This makes them ideal for demanding stage, rigging, and event applications where safety and reliability are paramount.

With these core standards, WTC ensures each truss delivers trustworthy performance under real-world conditions. Our commitment to excellence allows clients worldwide to rely on WTC truss systems for both everyday use and large-scale, complex installations.

Material Selection

Material Selection  Quality First

Quality First  Excellent Work

Excellent Work  Customers Satisfy

Customers Satisfy